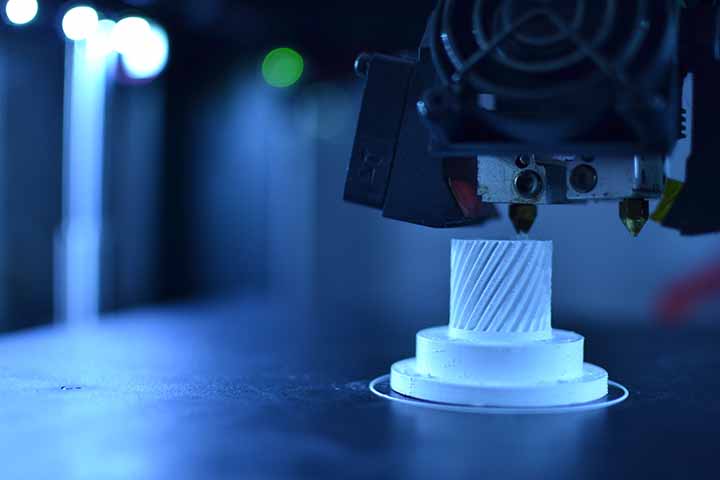

Notre ligne Zetamix by Nanoe rend disponibles nos poudres et leurs propriétés à la plupart des imprimantes 3D FDM. Inspiré par les procédés d’injection de poudres céramique, le process de fabrication Zetamix est constitué de trois étapes : l’impression, le déliantage et le frittage. Dense à 99 %, le produit fini bénéficie des mêmes propriétés que ceux fabriqués par méthodes traditionnelles.

Cette technologie a été développée grâce au programme de recherche et d’innovation Horizon 2020 de l’UE.

Cette technologie a été développée grâce au programme de recherche et d’innovation Horizon 2020 de l’UE.

Nos filaments avant frittage sont constitués de liants polymère et d’une proportion allant de 50 à 60% de poudre céramique. Nous proposons trois filaments : la Zircone blanche, la Zircone noire et l’Alumine.

Nous avons également développé un filament en acier inoxydable, et nous travaillons actuellement sur le développement de filaments carbure de silicium, de nitrure de silicium, de carbure de tungstène/cobalt et de titane.

Notre technologie a pour mission d’être accessible à tous et s’adresse aussi bien à l’industrie et aux laboratoires de recherches qu’aux artistes et aux designers. Nanoe propose non seulement les filaments mais également un pack composée d’une imprimante 3D d’une station à déliantage et d’un four.

Les trois étapes du process ont été pensées pour une prise en main rapide, et induisent des coûts d’investissement très faibles. Nos filaments étant compatibles avec la plupart des machines FDM du marché, notre technologie est un système ouvert. Le déliantage et le frittage peuvent aussi bien être effectués à l’aide de votre propre matériel qu’avec celui proposé par Nanoe.

Enfin, une formation est offerte avec le pack Zetamix durant laquelle un expert 3D vous accompagne pour l’impression et la finalisation de vos premières pièces.

Le système Zetamix est idéal pour le prototypage et la customisation de pièces. Il vous permet de créer des pièces en céramique ou en métal rapidement et à moindre coût. Cette technologie est recommandée pour l’outillage interne et permet de répondre facilement et dans des délais très courts à des problématiques de production variées.