Very high impact resistance | Very strong bending strength

In order to be used in the manufacturing of technical parts, pure zirconia is partially stabilized in tetragonal form thanks to the addition of a dopant, often 3% yttrium oxide. In this form, it is the most widely used material in the field of technical ceramics. It has excellent shock and bending resistance.

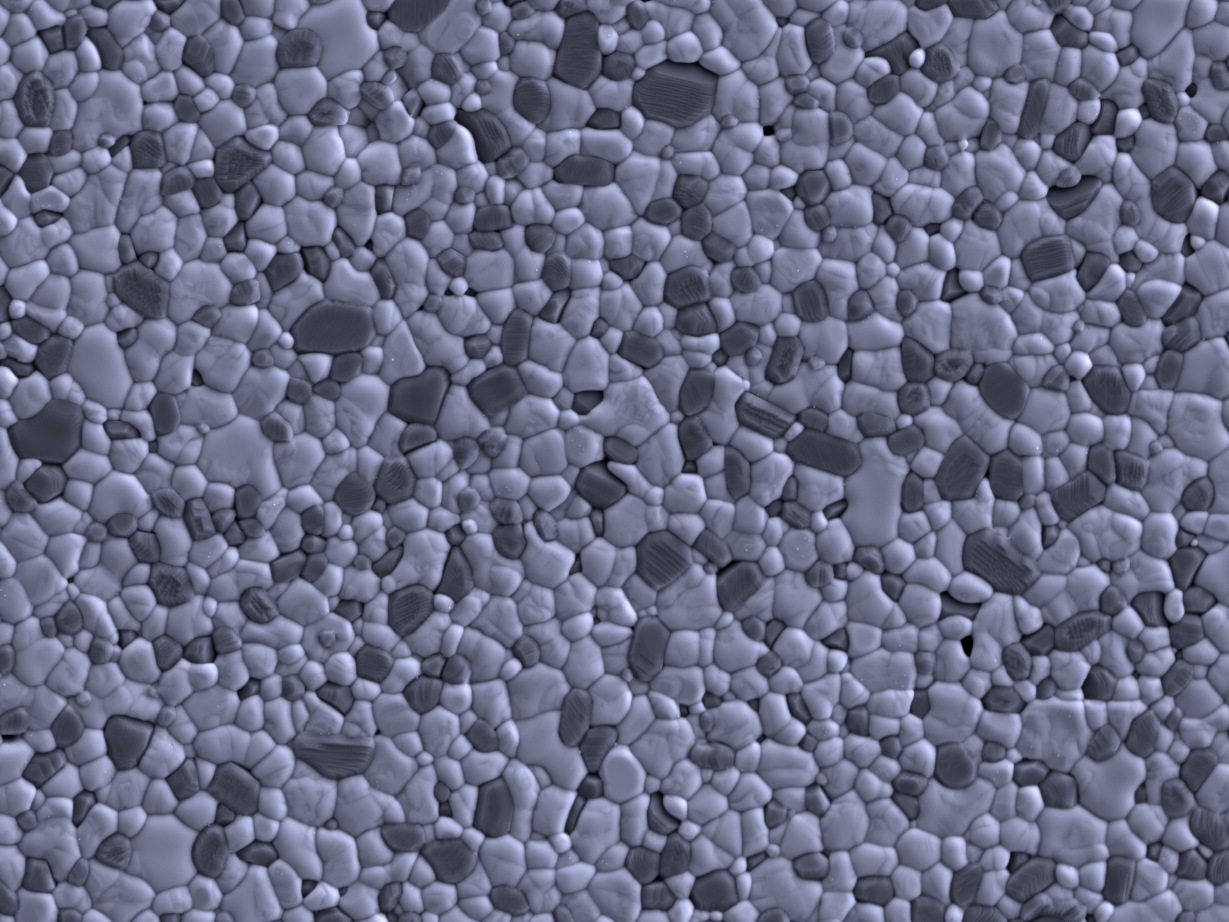

In addition to the yttria-stabilized zirconia (3Y-TZP), Nanoe offers an alumina-reinforced zirconia powder to improve its wear resistance, also called ATZ (Alumina toughened zirconia). The alumina-zirconia ratio proposed by Nanoe makes it possible to obtain better mechanical properties than zirconia alone. Combined with our unique knowledge of powder synthesis, this zirconia (ATZ) makes it possible to manufacture sintered parts with very fine grains ensuring remarkable mechanical properties.

Zirconia is recommended for medical applications and especially for the dental industry. They are also very used for make cutting tools, as coating and as a thermal barrier. Finally, they are used for a large number of mechanical applications where high bending strength is required.

In order to better respond to your needs, Nanoe delivers it’s zirconia under the shape best fitted for your process. We are able to provide our products as granules ready to press, redispersible powder or even as a feedstock for ceramic injection. Nanoe is also capable of adjusting the zirconia to best fit your demands and constraints ; e.g. adding a special doping agent in its composition.

Need advice to choose your material?